The RFID labeling solutions Metalcraft can provide using RFID passive tags and RFID inlays are amazing.

A business’ ability to manage warehouse inventory, delivery, and distribution with tags starts with the use of code characters programmed into a chip, an integrated circuit (ic).

Understanding the needs of the customer, converters (also called labelers) often procure standard chips and antennas attached to substrates from inlay manufacturers. Together, these pieces make up an inlay, which may be wet or dry depending on the converter’s need and, ultimately, the customer’s need.

When received by a converter, a TID code is already encoded, the converter encodes the unique serial number, the EPC code, which will match individual items in a customer's inventory.

The antenna’s construction may be standard too or made in consultation with converters.

Such collaboration will often occur when a tag customer has special needs. For example, a tag for a small item, such as a stud earring, may need a uniquely designed UHF antenna to accommodate item size and read range.

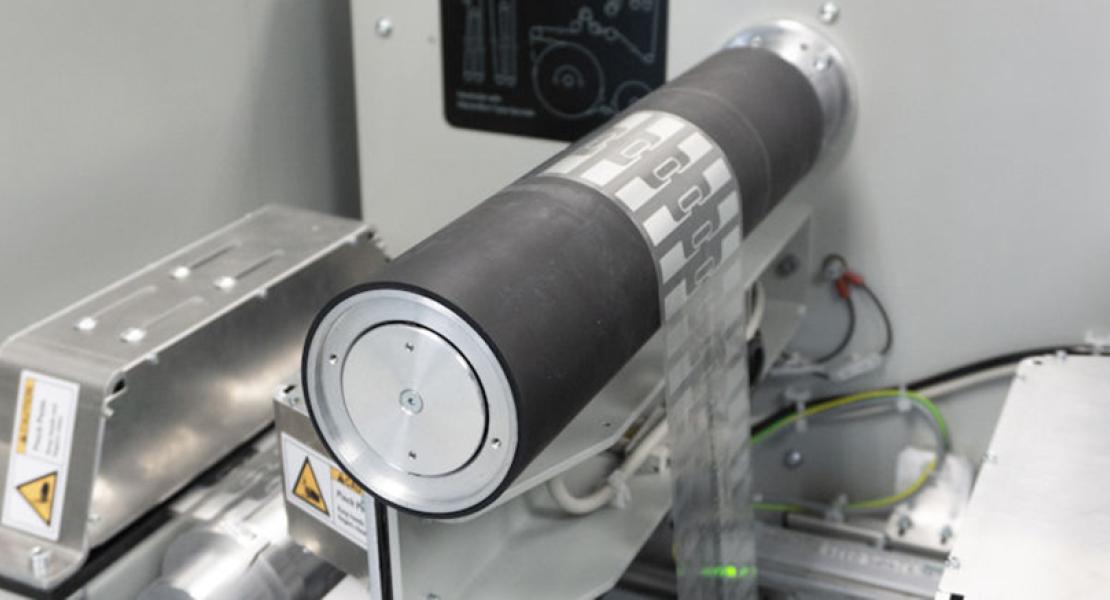

After construction, the best inlay manufacturers thoroughly test their inlays against industry standards; after construction, the best converters test their tags against industry standards and for in-field use perfection.

Metalcraft Focuses On Testing RFID Inlays

Metalcraft tests because a small mistake in chip/antenna placement can cause a change affecting tag behavior at the code level keeping tags from identifying intended items.

The same happens if antennas are broken during manufacturing. Both errors will cause tags to malfunction or cause programming errors.

Programmed improperly because of a tag manufacturing error, incorrect EPC codes might read tags such as ones on standard bicycle seats as banana seats or worse. An entire supply chain can be seriously impacted if a sequence of tags contains such errors.

Again for example, the brand that cuts clothing costs by offering goods that have been made and tagged in-house under less than ideal conditions, housed enmass, and handled thousands of miles in transit faces faulty tagging and retail RFID problems.

Purchasers, who are using RFID systems, leave themselves open to confusion and ROI concerns when confronted with poorly made tags.

Conversely, well-built tags, of Metalcraft quality, integrate seamlessly when they arrive to the customer. Abnormalities, should they exist, will be immediately detected in production, pulled, and rectified with a new tag.

Metalcraft Focuses On Tuning Of RFID Inlays

Different tags in different environments on different materials require specific antennas tuned to match the frequencies of the RFID system in place.

Sometimes the tuning of a specific tag is commonplace, especially when the energy goes through air to materials like plastic; then, a standard tag will do. Wood, however, may be problematic to the energy exchange, and metal and liquid materials will need special attention both in antenna and substrate selection for transponder/reader communication to take place.

Specialists like those at Metalcraft can diagnose your needs directing you to LF (low frequency), HF (High frequency), or UHF (ultra high frequency) antennas/tags with elliptical or linear polarity. (LF and HF are useful in short range read (near field) use, UHF is for longer reads (far field). Elliptical polarity is desirable when many tags are read at one time or at great speed; linear when selective data is to be retrieved or read zones are isolated.)

Magnetic fields within an environment must also be considered as well as tag collision concerns.

If a custom tag is needed, Metalcraft converters will craft a tag to fit the application through antenna design/tuning and substrate design-and do field testing of a prototype in the environment of use.

Metalcraft Focuses On Geography For RFID Inlays

Varying by country, the spectrum of radio frequency is government controlled. Tags have to be designed to meet the particular allocations of an area to be operable.

To meet the demands of regional purchasers and the demands of international commerce, tag retailers make efforts to meet a broad range of frequencies (840-956 MHz commonly used in UHF tags), but quality of use can vary from area to area.

The EPCglobal Gen2/ISO 18000-6C standard is commonly used for international tracking in most applications. Yet, some enterprises operate under their own frequencies so the use of external tags is questionable within closed system.

Knowledgeable converters consider the geographical location in which tags will be used and build accordingly.

Inlay purchasing, testing, tuning and location are all important when considering a labeling solution.

Technical backgrounding is a necessary part of an RFID tag build. Such backgrounding prior to a substrate build will lead to machine readable, permanent tags that will last the lifetime of the item to which it is attached.

An RFID tag is so much more than the polyesters and adhesives that one commonly thinks of in tag construction. It is expertise coupled with the correct protective and function layering that give manufacturers, wholesalers and retail consumers amazing tags that benefit their management potential.

To learn more about our RFID tags, contact us today at [email protected].

| About the Author: Aaron HobertAaron Hobert is our RFID Technical Specialist. Hobert joined Metalcraft in September of 1994 as a Litho Press Operator, became the Autograph Team Lead in 1998 and in April 2005 he became the RFID Sales Support Rep. He was named our RFID Technical Specialist in 2008. Aaron lives outside Charles City with his wife Diane. Mobile Phone: 641-330-2660 Email: [email protected] Office: 3360 9th St. SW, Mason City, IA 50401 Office Phone: 641-423-9460 |